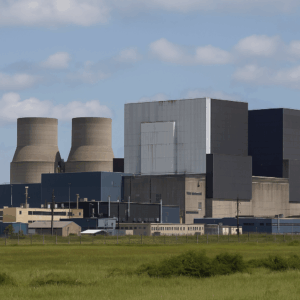

Two of Britain’s nuclear power stations : Heysham 1 in Lancashire and Hartlepool in County Durham, have recently been granted one-year lifetime extensions, keeping them operational until at least March 2028.

These plants were built in the early 1980s, with an original design life long since exceeded. Yet, due to ongoing energy security challenges, the cost of new replacements, and positive inspection results on their graphite reactor cores, the UK government and EDF Energy have decided that extending their use is the best strategic option.

This decision highlights a reality many industries face: critical systems often need to operate well beyond their intended lifespans.

Why This Matters Beyond Nuclear

While nuclear power plants grab headlines, the same pressures apply across manufacturing, utilities, transport, defence, and infrastructure:

Cost of replacement is prohibitive: Large-scale rip-and-replace projects require budgets, downtime, and approvals that are often unrealistic in the short term.

Delays in new projects: Just as new nuclear builds take decades, new industrial systems can be years away.

Safety and regulation demand reliability: Systems cannot simply fail, they must keep running safely, even if their components are obsolete.

Hidden degradation: In nuclear plants, graphite cores were the focus. In electronics and control systems, the risk may lie in aging circuit boards, capacitors, connectors, or outdated firmware.

In short, legacy systems aren’t going away anytime soon. The challenge is keeping them reliable, safe, and cost-effective until the right time to modernise.

Obsolescence Support as a Strategy, Not a Stopgap

The extensions at Heysham and Hartlepool weren’t acts of desperation. They were strategic decisions backed by rigorous inspection and risk management.

That’s exactly how we see obsolescence support at Amelec:

Assessment & Audit: Identifying where your systems are most at risk from aging or discontinued components.

Sustainment & Support: Providing replacements, re-engineered solutions, and technical expertise to keep your equipment running.

Bridging & Hybrid Solutions: Integrating legacy systems with newer technologies so you don’t need to choose between “all or nothing.”

Modernisation Roadmaps: Planning ahead so that when replacement is feasible, it’s smooth and disruption-free.

Like the nuclear sector, we know that running legacy systems safely and effectively is a strategic choice — one that buys you time, avoids costly downtime, and keeps your operations secure.

The Risks of Ignoring Legacy Systems

The danger comes when organisations do not plan for obsolescence. Some of the risks include:

Unexpected downtime when a critical part fails with no replacement available

Escalating maintenance costs as workarounds pile up

Cybersecurity exposure from outdated firmware or unsupported software

Compliance and audit failures due to reliance on unmaintained equipment

Ignoring obsolescence until a crisis strikes can be far more costly than proactive management.

Learning from Nuclear: Extend with Confidence

If even nuclear power plants, among the most scrutinised and safety-critical facilities in the world — can be extended safely with the right monitoring and support, then so can your critical systems.

The key is proactive obsolescence management. At Amelec, we provide the expertise, products, and support services that allow you to operate with confidence, knowing your legacy equipment is in safe hands.

Next Steps

Download our checklist: 10 Signs Your System May Be at Obsolescence Risk (Or contact us)

Book a free consultation: Let us assess the health of your legacy equipment and outline support options.

Stay informed: Subscribe to our updates for the latest on obsolescence strategies, industry news, and support services.

At Amelec, we make that possible.

📞+44 (0)1908 567003

📧 sales@amelec-uk.com

🌐 www.amelec-uk.com